Electric Vehicle Supply Chains Risk Creating Pollution Hotspots, Study Finds

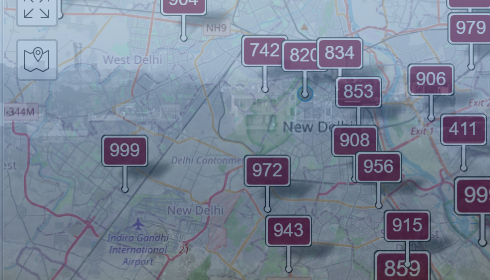

While electric vehicles (EVs) continue to be a key driver of the global energy transition, a new study led by Princeton University reveals a significant environmental tradeoff: refining critical minerals for EV batteries may result in pollution hotspots near manufacturing hubs, particularly China and India. The study, published in Environmental Science & Technology, emphasizes the critical need for cleaner supply chains and smart air pollution measures to avoid the unintended consequences of the electric vehicle boom.

According to the report, fully domesticating EV supply chains in China and India could result in up to a 20% increase in national sulphur dioxide (SO₂) emissions. Who are the key culprits? They are refining nickel and cobalt, two essential materials used in most EV batteries today.

"Many discussions about electric vehicles focus on minimizing emissions from the transportation and power sectors," said Wei Peng, the corresponding author and assistant professor at Princeton University's Andlinger Center for Energy and the Environment. However, Wei Peng demonstrates that the effects of electric vehicles extend beyond vehicle tailpipe emissions and electricity, affecting your entire supply chain.

China and India: Two approaches, one challenge

China and India, already experiencing severe air pollution, confront distinct hurdles in reducing SO₂ emissions from battery manufacturing. In 2019, fine particulate matter (PM2.5) combined with SO₂ emissions caused 1.4 million premature deaths in China and 1.7 million in India.

Peng's team found that, although China now has a domestic EV supply chain, India is still in the early phases of development. This differentiation involves both risks and opportunities.

"China needs to be thinking about how to clean up a supply chain that already exists, while India has the opportunity to build a better supply chain from the ground up," Peng says.

Researchers in India highlighted the power sector as a priority. Tough controls on SO₂ emissions in thermal power plants, like desulfurizing the flue gas, can stop more damage to the environment as the supply chain grows. China, which has already made progress in power sector regulations, has to focus on improving battery manufacturing processes to reduce SO₂ emissions.

The Hidden Tradeoff in Clean Energy

The researchers warn against disregarding pollutants from battery production. Even with cleaner grids, SO₂ emissions from nickel and cobalt processing continue unless battery production processes are addressed directly.

"People generally assume the transition to greener technology is always going to be a win-win—there will be climate and air quality benefits," said Anjali Sharma, initial author and now assistant professor at IIT Bombay. "But without considering manufacturing, you might reduce carbon and nitrogen oxide emissions but end up increasing the air pollution burden for communities near manufacturing centers."

Global Implications and Solutions.

Although the study focuses on China and India, the researchers suggest that SO₂ pollution from EV battery production is a global issue. Outsourcing battery manufacture does not reduce emissions; it simply shifts pollutants to other countries.

"It's important to look at electric vehicles from a global supply chain perspective," Sharma reminded attendees. "Even if India imported batteries, the pollution would not disappear. The pollution would simply shift to another nation.

To prevent the unforeseen consequences of EV production, the researchers propose proactive policy measures, such as tight national air pollution limits. Furthermore, finding alternate battery chemistries may assist in reducing the environmental costs associated with nickel and cobalt processing.

One prospective answer is the development of lithium iron phosphate (LFP) batteries, which use iron and phosphate instead of cobalt and nickel. LFP batteries produced significantly lower SO₂ emissions during manufacture.

Human-Centred Energy Transition

The findings serve as a timely reminder that even clean energy technology has tradeoffs that might affect communities. Wei Peng concludes: "We are aware of numerous important technologies for reducing carbon emissions. The other half is how these technologies will affect individuals. My approach involves considering the most effective methods for technology and people to interact, as these tactics are likely to yield the best results for the largest number of individuals.

As the globe moves toward electrification, this study emphasizes the significance of ensuring that the energy transition prioritizes environmental integrity and public health, particularly in locations at the heart of battery supply chains.